- Home

- Science

- Science News

- MIT Develops 3D Printable Aluminum Alloy That’s Up to Five Times Stronger Than Conventional Metals

MIT Develops 3D-Printable Aluminum Alloy That’s Up to Five Times Stronger Than Conventional Metals

MIT’s 3D-printed aluminum alloy is five times stronger than cast metal and could transform aircraft and industry.

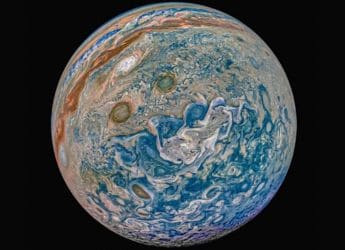

Photo Credit: Felice Frankel

MIT’s new 3D-printed aluminum shows a dense structure that delivers record strength and heat resistance.

MIT researchers have developed a new aluminum alloy that can deploy 3D printing and is much stronger than standard products, in fact, it could be five times stronger. The metal, developed through the novel simulation and learning methods, is stable at high temperatures. When it's printed, a lot of the internal structure of the model fuses together very well, making for a strong and functional model. The advance could make it possible to replace today's heavier, more expensive materials used in aircraft engines, cars, and high-performance industrial systems.

MIT's AI-Designed 3D-Printed Aluminum Matches Titanium Strength at a Fraction of the Weight

According to an MIT report published in the journal Advanced Materials, the new alloy was developed by mixing aluminum with selected ingredients found by machine-learning models. These tools reduced more than a million possible combinations of materials to 40 good prospects, sparing years of trial-and-error experiments. Laboratory tests demonstrated that the printed alloy was as strong as the best traditionally made aluminum, while being much lighter than materials such as titanium.

The new alloy's strength comes from its internal structure: rapid 3D printing cooling forms dense, evenly distributed precipitates, making aluminium stronger, unlike slow casting, which weakens the metal by enlarging features.

From Classroom Concept to Industry Game-Changer: MIT's New Alloy Targets Aviation, Autos, and Data Centers

The development team also notes the alloy's wide industrial potential, providing lightweight high-strength aluminium with applications in aviation, automotive, a vacuum system, and a data centre cooling system based on its strength and heat holders, as well as cost next to titanium components.

MIT classroom challenge soon turned into research, as scientists worked to perfect the alloy and expand methods to include other metals with a hope of revolutionizing 3D printing with lighter, stronger machines.

Get your daily dose of tech news, reviews, and insights, in under 80 characters on Gadgets 360 Turbo. Connect with fellow tech lovers on our Forum. Follow us on X, Facebook, WhatsApp, Threads and Google News for instant updates. Catch all the action on our YouTube channel.

Related Stories

- Samsung Galaxy Unpacked 2026

- iPhone 17 Pro Max

- ChatGPT

- iOS 26

- Laptop Under 50000

- Smartwatch Under 10000

- Apple Vision Pro

- Oneplus 12

- OnePlus Nord CE 3 Lite 5G

- iPhone 13

- Xiaomi 14 Pro

- Oppo Find N3

- Tecno Spark Go (2023)

- Realme V30

- Best Phones Under 25000

- Samsung Galaxy S24 Series

- Cryptocurrency

- iQoo 12

- Samsung Galaxy S24 Ultra

- Giottus

- Samsung Galaxy Z Flip 5

- Apple 'Scary Fast'

- Housefull 5

- GoPro Hero 12 Black Review

- Invincible Season 2

- JioGlass

- HD Ready TV

- Latest Mobile Phones

- Compare Phones

- Tecno Pova Curve 2 5G

- Lava Yuva Star 3

- Honor X6d

- OPPO K14x 5G

- Samsung Galaxy F70e 5G

- iQOO 15 Ultra

- OPPO A6v 5G

- OPPO A6i+ 5G

- Asus Vivobook 16 (M1605NAQ)

- Asus Vivobook 15 (2026)

- Brave Ark 2-in-1

- Black Shark Gaming Tablet

- boAt Chrome Iris

- HMD Watch P1

- Haier H5E Series

- Acerpure Nitro Z Series 100-inch QLED TV

- Asus ROG Ally

- Nintendo Switch Lite

- Haier 1.6 Ton 5 Star Inverter Split AC (HSU19G-MZAID5BN-INV)

- Haier 1.6 Ton 5 Star Inverter Split AC (HSU19G-MZAIM5BN-INV)

![[Partner Content] OPPO Reno15 Series: AI Portrait Camera, Popout and First Compact Reno](https://www.gadgets360.com/static/mobile/images/spacer.png)